Aviation Fuel Life Cycle Analysis

Life Cycle Associates is a recognized leader in conducting life cycle analyses of aviation fuels. We developed a proprietary life cycle model (LCM) that models the environmental sustainability impacts of several petroleum and alternative aviation fuel pathways. To date, our team modeled jet fuel produced from vegetable oils, photosynthetic and heterotrophic algae, and FT jet fuel derived from municipal solid waste and biomass using analysis tools for aviation fuel polices.

The analyses conducted by Life Cycle Associates are based on life cycle inventory data extracted from the 2024 40BSAF-GREET model, as well as LCI data from sources such as GHGenius and the EU JRC and CORSIA studies. The analysis includes field-to-pump analysis and pump-to-wake analysis, which is based on emission factors and energy use data for specific aircraft/engine combinations for the landing/take-off and cruise phases of flight.

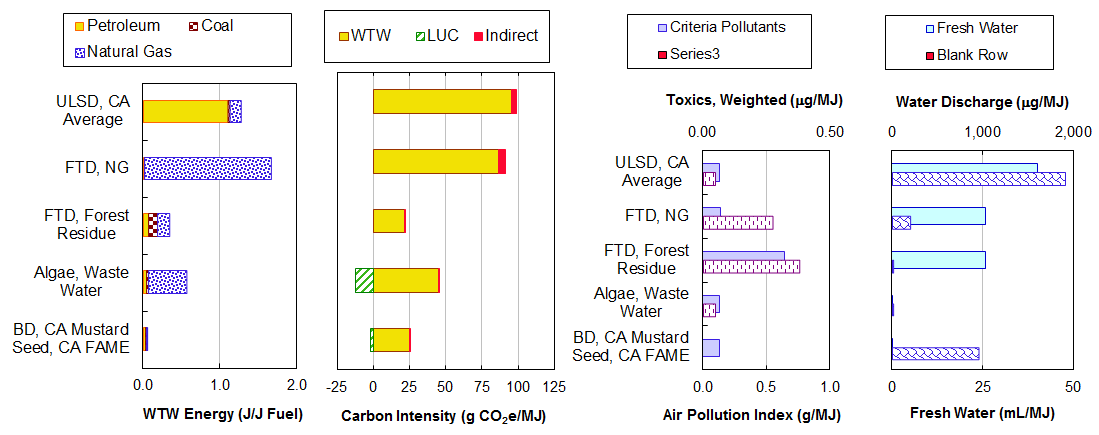

The life cycle analysis is also expendable to other environmental impacts of interest, including water use, land use, and biodiversity, as well as any fuel pathway scenario. The analysis shown here examines regionally specific water consumption and withdrawal, in addition to energy use, greenhouse gas emissions and criteria pollutants.

The analysis is adaptable to SAF from any feedstock and conversion process and Life Cycle Associates seeks to work with feedstock and fuel producers to evaluate their aviation fuels and support future certification and verification.

Experience with Broad Range of Feedstocks and Conversion Technologies for Sustainable Aviation Fuels

Life Cycle Associates has worked on a broad range of feedstocks and conversion technologies for both sustainable aviation fuels (SAF) as well as on-road transportation fuels. Each of the feedstocks shown in the table have characteristics that affect their upstream life cycle footprint. Those vary with different GHG policies such as the RFS, LCFS, and CORSIA.

Furthermore, the processing technologies involve different unit operations such as hydrotreating or ligamentization. Estimates of the processing emissions are often not available from developers. Our understanding of the mass and energy balance of conversion processes is essential in determining the overall environmental footprint.

Finally, the certification and verification requirements under the LCFS and CORSIA require careful attention to data collection record. Complete record keeping and compliance with the analysis tools are required for each policy. For example, SAF is examined as a co-product to renewable diesel for hydrotreating pathways under the Low Carbon Fuel Standard while Tier2 pathways for gasification and FT synthesis are still under development.

|

Feedstock |

Technology |

|

Algae |

Hydroprocessing |

|

Oils and Fats |

Hydroprocessing |

|

Ethanol |

Dehydration, |

|

Dextrose |

Catalytic conversion |

|

MSW Woody Biomass |

Gasification, |

| Landfill Gas |

Reforming, |

Analytical Framework for Aviation Fuel Evaluation

Life Cycle Associates has assessed existing sustainability analytical frameworks and developed an analytical framework suitable for aviation fuel evaluation. The study summarizes the issues associated with verifying the sustainability of alternative aviation fuels. The challenges of developing a prospective GHG rating for technologies that are under development are significant because commercial aviation operates globally, and fuels would be subject to different regulatory requirements. However, fuel technology developers need to understand the policy and incentive implications of feedstock sourcing and design decisions to establish the economic viability of a project.

Knowledge of Regulatory Requirements and Co-Products

Life Cycle Associates also works with fuel technology developers to develop carbon intensity ratings under the RFS2, LCFS, CORSIA and RED. Co-products including naphtha, paraffin, waxes, and fermentation products have a significant impact on the life cycle impacts. We examine the co-products credits that are consistent with the analysis method used for each fuel policy and modeling system.

Questions

Do you have questions about our experience with aviation fuel life cycle analysis?